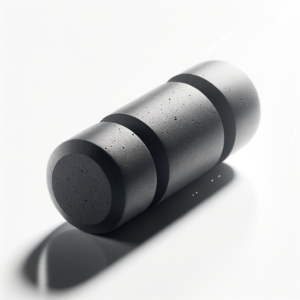

Rubber buffers are an indispensable component in various industries, offering versatile solutions for vibration damping and impact absorption. These resilient devices have proven their worth in countless applications, providing a range of benefits that extend equipment lifespan and enhance overall operational efficiency.

Types of Rubber Buffers

Rubber buffers come in various shapes and sizes, including cylindrical, square, and conical configurations. Each type is designed to cater to specific needs and requirements. Cylindrical rubber buffers, for instance, are commonly used to absorb shocks and reduce vibrations in heavy machinery, while square rubber buffers find applications in the automotive industry for isolating vibrations and noise.

Advantages of Rubber Buffers

The advantages of using rubber buffers are manifold. These simple yet effective components play a crucial role in reducing noise levels, ensuring a quieter work environment. Additionally, they help in protecting equipment from excessive vibrations, thus extending its operational lifespan. This leads to reduced maintenance costs and enhanced productivity.

Common Applications

Rubber buffers are deployed across various industries, from construction to transportation, and manufacturing to healthcare. In construction, they are used to dampen vibrations in heavy construction machinery, while in the automotive sector, they isolate vibrations in engine mounts. Even in everyday life, rubber buffers can be found in furniture to reduce the noise and impact when doors or drawers are closed.

Choosing the Right Rubber Buffer

Selecting the appropriate rubber buffer for a specific application is crucial. Factors such as load capacity, environmental conditions, and the expected level of vibration play a significant role in the decision-making process. Engineers and project managers should carefully evaluate these factors to ensure optimal performance.

Installation and Maintenance

Proper installation of rubber buffer is essential for their effectiveness. Following manufacturer guidelines and industry best practices is essential. Regular maintenance is also key to ensure that the rubber buffers continue to perform as expected. Inspecting them for wear and tear, and replacing them when necessary, can prevent potential issues down the line.

Case Studies

Several case studies demonstrate the positive impact of rubber buffers in various industries. For instance, in the mining industry, the installation of rubber buffers in conveyor systems resulted in a significant reduction in equipment downtime and maintenance costs. Similar success stories can be found in the manufacturing sector, where rubber buffers contributed to smoother and quieter operations.

Future Trends

As technology continues to advance, rubber buffers are also evolving. Smart rubber buffers with sensors and predictive maintenance capabilities are on the horizon, promising even more efficient vibration damping and impact absorption solutions. These innovations are expected to revolutionize industries that rely heavily on equipment performance and longevity.

Environmental Considerations

In an era of increased environmental awareness, the sustainability of materials used in rubber buffers is gaining importance. Many manufacturers are exploring eco-friendly options and recycling possibilities to reduce their carbon footprint. This aligns with the global effort to reduce the environmental impact of industrial processes.

Conclusion

Rubber buffers have proven themselves as indispensable components in various industries, offering effective solutions for vibration damping and impact absorption. Their advantages include noise reduction, equipment protection, and cost savings. Choosing the right rubber buffer, proper installation, and regular maintenance are key to maximizing their benefits. As technology continues to advance, we can expect even more innovative solutions in the field of vibration damping and impact absorption. Embracing these trends while considering environmental sustainability will ensure that rubber buffers continue to play a vital role in numerous industries.